Glass Crusher and Tritium Removal System

Model: 7035-GLASC-001

Application

Tritium lights facilities or tritium laboratories wishing to remove tritium from glass tubes or small metal or ceramic components.

Features

-

Crushes glass bulbs from tritium light industry to expose internal surface and remove tritium from glass

-

Removes tritium from the waste glass or from small metal specimens

-

Places the tritium safely on getter beds for future use or permanent storage.

-

Reduces radioactive material storage costs

-

Serves important miscellaneous uses for the tritium laboratory.

Description

The equipment comprises two separate units, a glass crusher for tritium light tubes, and a tritium removal system that can be used with the tritium glass crusher, but which may also be used with the small furnace supplied on top of this equipment.

The glass crusher is a stainless steel vessel, which can be fully evacuated. It contains a carousel into which can be loaded tritium light bulbs from which tritium is to be removed. By turning a handle once the bulbs have been loaded the glass tubes, of various sizes from 1 inch to 6 inches will be crushed.

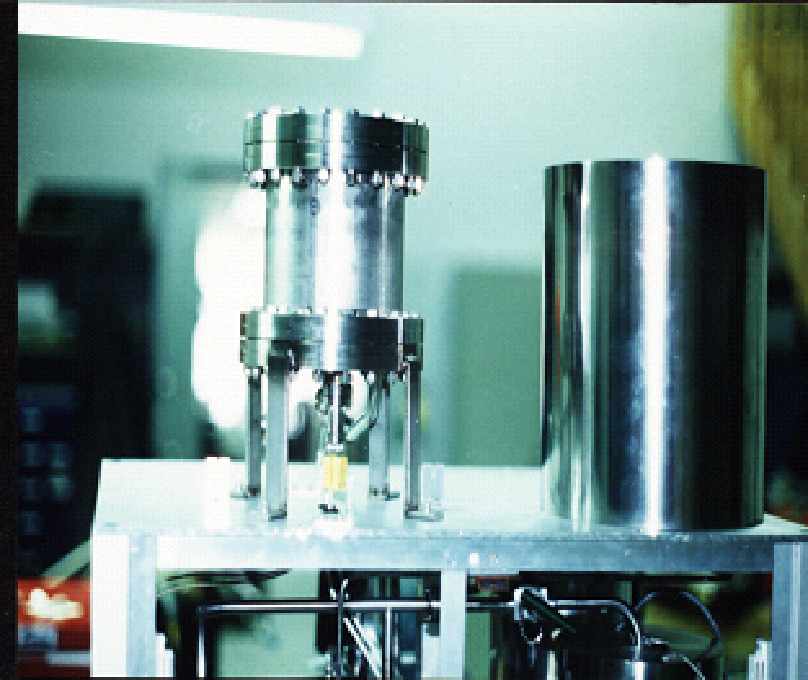

system with side panels removed

There are two modes of operation: Removal of tritium from glass by crushing, and removal of tritium from miscellaneous tritiated specimens. Each are described separately below.

Furnace with protective cover removed mounted on top of the Circulation Equipment cabinet.

If the glass crusher mode is used, it is assumed that the outside of the glass tubes are clean. The inside of the crusher vessel containing the tubes therefore may be evacuated directly to stack before the tubes are crushed. Then after crushing, to get the tritium from the glass, the vessel is flushed with helium that is subsequently circulated through a cooler, a cryotrap, and then through a uranium bed to capture the tritium.

If the high temperature furnace mode is used to remove tritium from specimens, the furnace is evacuated after the specimens are installed but before heating. Since the specimens may contain some free HTO the exhaust will be passed through a mol sieve bed to capture tritium before release to stack via the getter bed.

Samples of glass Light Tubes ready for crushing

The furnace is then heated, helium continues to be circulated through it, the gas is cooled, passed through a molecular sieve bed and to a uranium bed if that is how final storage is to be achieved. Provision can be made to transfer tritium from the uranium to a permanent storage bed if required.

The furnace heats the specimen crucible at temperatures up to 750 °C. The vacuum pumping system comprises a Varian SD40 vacuum pump, and a MB 158 helium circulating pump which is able to operate in a vacuum and is chosen for its reliability.

The equipment can be made to operate automatically, but in most cases a manual

switching system is suitable. This incorporates pneumatically operated valves, manually switched via solenoids mounted on a panel. This arrangement keeps the assembly compact, reliable and easy to operate via a mimic diagram mounted on the front of the cabinet. The use of pneumatic valves enables the design to utilize shorter tubing runs and results in lower inventory.